LCoS Panels

LCoS - Liquid Crystal On Silicon

The LCOS technology is the newest one on the block. It uses the simplicity and cheapness of a standard LCD, Developed as D-ILA by JVC

and SXRD by Sony LCOS effectivley moves the LCD wiring from the cell sides to the back of the panel allowing the fill factor to equal

that of DLP - 93%. Lcos's reduction of visible pixelation on the projected image means the gap between the pixels is so small

that even when the image is projected to a 3m diagonal, it is still not possible to see the edges of the pixels

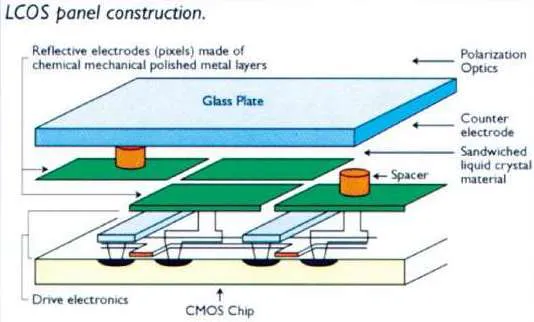

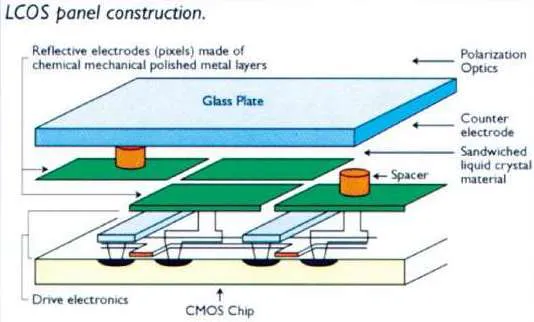

The 3-Chip version of the system beams pre-coloured red, green and blue light into three separate LCOS chips. The light is

simply run through a polarizing filter and aimed at the chip. At the chip, the light pases through the LCD layer, reflects off the back

surface and passes back through the LCD layer. The light then exits the chip and heads towards a second polarizing filter. The three

separate coloured images are combined into one image using a prism, and then projected through stand lens optics onto a screen.

It is very likely that LCOS will quickly move to completely replace conventional LCD, largely because of the cost effectiveness of production

and two major optical advantages. The first of the two optical advantages are that the pixel pitch (space between pixels) is at least as good

as and possibly better than D-ILA. Secondly, the quality of blacks can be enhanced due to the fact the light has to pass through the LCD layer

twice before leaving the projector.

LCOS panel construction

DLP and LCOS pixel visability