SXRD - Silicon X-tal*1 Reflective Display

Sony's LCOS panel - SXRD stands for Silicon X-tal Reflective Display. A display device for use in projectors, which achieves a

panel contrast of over 30000:1 with high resolution of Full HDTV(1920Hx1080V)jusing a silicon backplane. Its main features are:

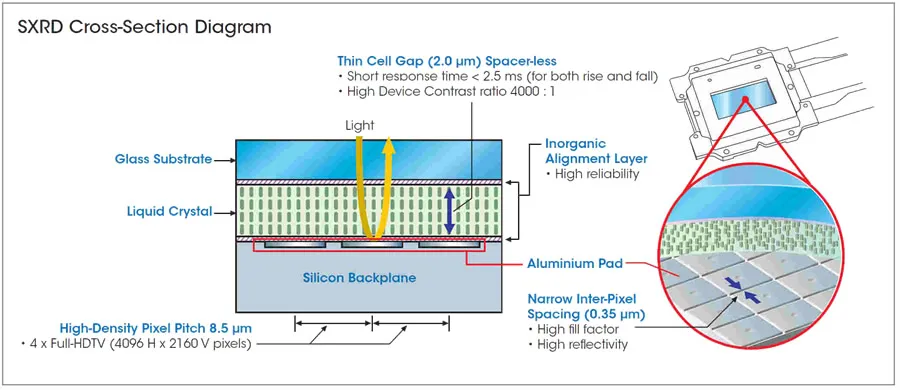

High Resolution Picture Quality

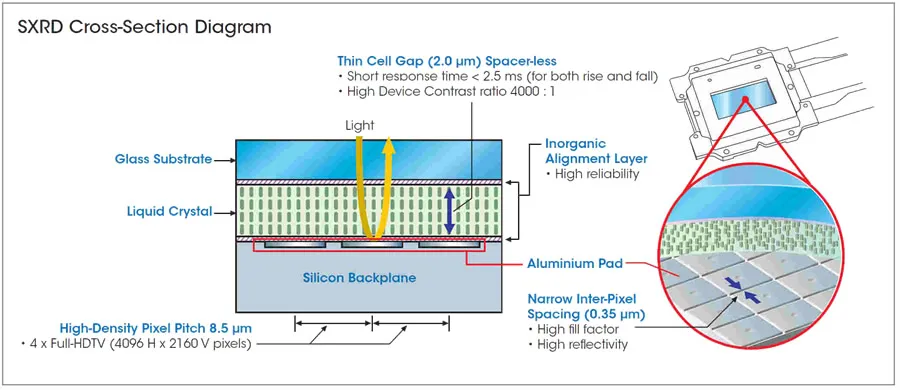

The outstanding picture quality generated by SXRD is due to the large number of pixels contained within the image area

of the device. For this to be achieved both the size of each individual pixel and the space between pixels has been minimized.

The combination of radically designed Silicon Driving Circuit technology and novel Silicon Wafer Process Technology, coupled

with new Liquid Crystal Device technology, has enabled 2,000,000 pixels with a pitch of 9um to be arranged just 0.35um apart

(Diagram1-a). This is the world's smallest inter-pixel spacing*2 thus delivering full HDTV (1920Hx1080V, 16:9 widescreen

format) within an image area measuring a mere 0.78 inches diagonally across.

Sony SXRD chip

In comparison to high temperature Poly-Silicon liquid crystal devices, this represents a 2.4- fold increase in pixel density, and

a 10-fold improvement in inter-pixel spacing.

These advances have facilitated the achievement of a high-grade, high-resolution picture quality previously unseen on fixed-pixel

projection devices, with outstanding cinematic quality and image smoothness that can be enjoyed free from the grainy "mesh" effect

noticeable on conventional projectors.

High Contrast and Rapid Response Time

In Sony's SXRD device the liquid crystal cell gap measures less than 2um, far thinner than conventional high temperature

Poly-Silicon liquid crystal or LCOS(Liquid Crystal On Silicon)devices (Diagram1-b). Furthermore, in place of the TN(Twisted Nematic)

liquid crystal commonly used in projection devices, Sony's unique "Vertically Aligned Liquid Crystal" materials,

whereby the liquid crystal molecules are aligned vertically to the cell substrates have been used.

The materials have been developed to provide good driving voltages and high quality optical properties, even in such thin cells,

ensuring high contrast images that would otherwise be unachievable with conventional TN devices (Diagram1-b).

These innovations have made a high panel contrast level of 3000:1, and very rapid 5 milli-second response time a reality.

This represents an approximately threefold increase over conventional projector contrast levels.

High Frame Rate for ultra-smooth pictures

SXRD projectors use a vertically aligned nematic liquid crystal that changes state with lightning-fast speed.

This enables the microdisplay to run up to 200 frames per second with minimal motion smear. Combined with the ultra-thin liquid crystal cell

gap, this enables our SXRD technology to project images of a quality surpassing DLP projectors. Every detail is clear, with no jagged edges

or visible pixels.

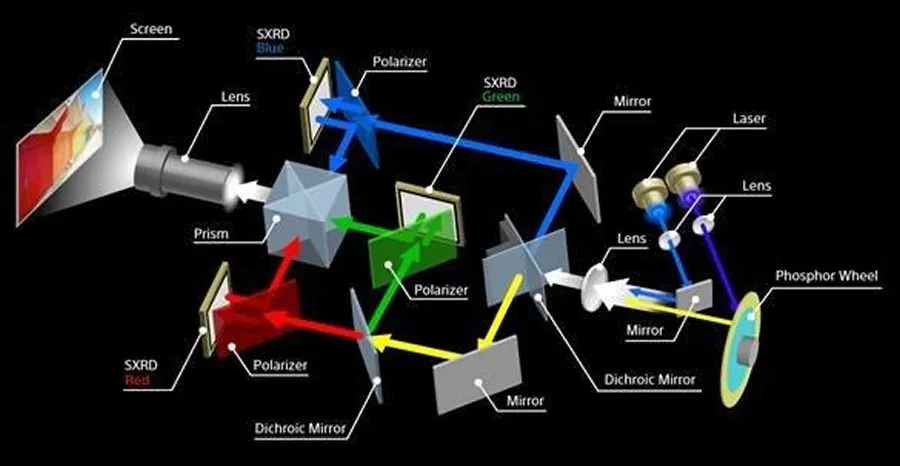

Blue Laser System

Laser Phosphor Technology based on SXRD Technology

Primary colours are created from the two blue lasers, Green created with a phosphor wheel. Generates improved colour and

brightness uniformity.

- Excellent colours and very good brightness uniformity

- Exceptional contrast

- High brightness

- DCI (Digital Cinema Initiative) compliant colour space

Sony SXRD Laser projection

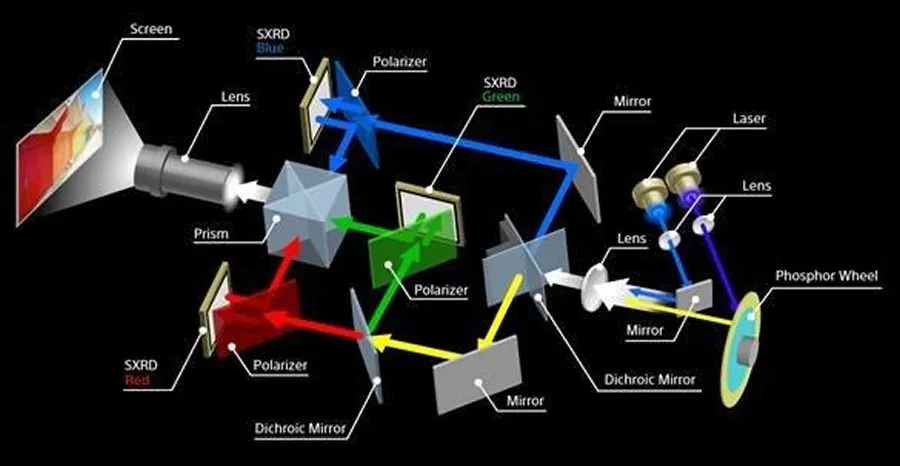

RGB Laser System

Laser Phosphor Technology based on SXRD Technology.

RGB laser uses primary colour technology. Red, green and blue lasers are delivered directly to the image chips.

This technology allows the creation of a large colour space that easily exceeds even that of Adobe-RGB or DCI and can

already cover the demanding Rec. 2020 colour space.

- Best colours and brightness uniformity

- Highest brightness

- Rec. 2020

Reliability

Sony has overcome the long-standing challenge of incorporating an inorganic alignment layer to the liquid crystal cell,

enabling the alignment technology of vertically aligned liquid crystals which has been problematic until now. This inorganic material

has successfully replaced the organic polyimide film previously used to align the liquid crystal. This innovation has greatly improved

alignment layer durability, ensuring the longevity of the high-resolution, high-grade features of the SXRD device

Sony SXRD panel construction

Combined High Product Quality and Production Efficiency

With conventional projection devices, in order to ensure uniform cell gap, the substrates must be assembled one at a time in a

piecemeal fashion. At the same time, spacers such as beads or posts known as "columns" would also need to be inserted within

the display area of the liquid crystal cell. However, in the case of the SXRD device, through the development of Planarization Technology of

Silicon Backplane, and alignment layer fabrication process, Sony has established a means of assembling entire wafers, even without the use of spacers. Thus many

panels are created at once in unison. This process has significantly reduced dust ingress, while simultaneously improving both picture quality and production

efficiency

The features and capabilities of the"SXRD"technology make it ideal for use in front projectors and rear projection TVs

of home theater dimensions, capable of delivering the high resolution, high-grade content that is becoming increasingly prevalent. The move

towards content of this nature is set to continue with the forthcoming launch of terrestrial digital broadcasting in the near future.

Sony aims to introduce front projectors and rear projection products incorporating this technology to the market within the next fiscal

year.